+86-769-21611190

info@wkplastics.com

About Us

You are here : Home / About Us

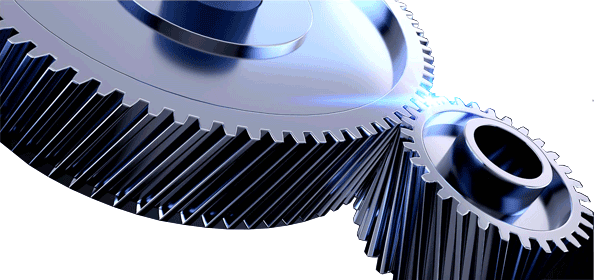

Established in 2000, WKPLASTICS provides global customers with high quality plastic gears, gear molds, engineering solutions and precision spare parts for multiple industries.

We have built a strong reputation for making tight tolerance helical gear mold, worm, spur, or bevel gear tooling and strive to be the first rate choice of our clients.

WKPLASTICS is a gear premier molding factory.

<< A powerful gear solution provider.

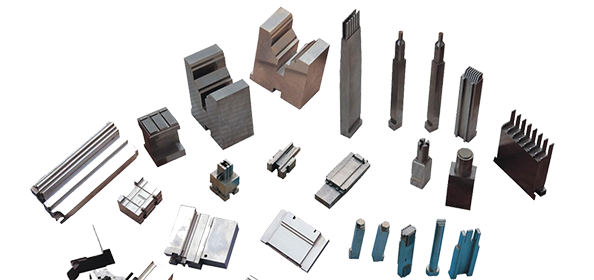

<< Full service tooling and mold making company .

<< Engineering solutions from concept to realization .

<< ISO 9001 & IATF 16949 certified injection molding facility .

<< Osaka precision JIS testing center for quality assurance of plastic gears

<< Professional HAMAI gear hobbling machine to process electrodes for helical or worm gear mold .

<< 50 injection presses from Sumitomo, Nissei, Toyo, Toshiba, etc to support part quality and affordable molding cost .

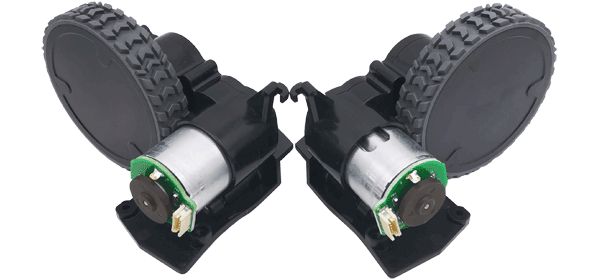

We utilize fully automatic injection molding machines from Japan and veteran operators to meet market needs.

Our presses range from 15 to 180 tons to produce plastic gears and other precision parts.

In 20 years, from a tiny mold part processing workshop, to a gear molding factory, to a modern injection molding production company with helical gear mold building capability and plastic gear testing center, we are proud of our choice, growth and development.

Plastic resins POM, ABS, PC, PC+ABS, PA, PP, PBT, TPE, TPU, PS, PET, etc and special ones PPS, LCP, PPS, PEEK, ETFE, PA12, etc are available here for producing plastic components.

WKPLASTICS stays long and competitive in its philosophy of "customer-oriented, precision-first and persistent improving". All staff members of WKPLASTICS have been making constant tireless effort to meet customer expectations. Our success story lies in a deep understanding of technology and of customer's specifications, our great vision, high quality awareness and the desire to never stand still.

Today, the fields we are engaged in with our international customers have covered electronic & electricalS, automotive industry, intelligent home, medical field, industrial automation...